Remove (and put back) the Hook on Singer 66 99

Text reads:

To Remove the Sewing Hook

1) Remove the oscillating hook slide, presser foot, throat plate and bobbin case.

Note: if you are working on a REAL OLD 66, like from a treadle cabinet - the bobbin case is a bit more difficult to remove. It will come out easier in step 3.

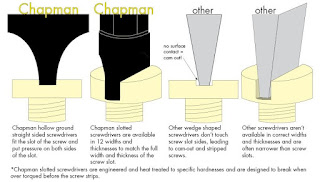

2) Turn the machine over on its hinges, take out the screw (N, Fig 8) and remove the feed dog. (I use Chapman Bit #93)

First item to note here - is that there are TWO versions of the bobbin case position bracket. So it's not going to make any sense if you are working on a hundred year old machine. See the picture below to understand the difference.

So this step is valid on a Model 99 and later Model 66's. Solid Hand Wheel is a good rule of thumb here. If it's a solid wheel - there is a set screw under the machine bed that releases the riveted Pin seating the bobbin case position bracket. The next photo is the set screw they are talking about. If that set screw isn't on your machine, then you are looking at the OLDER model, which I'll get into after.

So if you SEE this set screw - you'd need to loosen (or I would remove personally, so I can stick oil, PB Blaster or whatever it takes to get all that gunk out of there) to release the Bobbin case position bracket. Once that set screw is super loose (or out) the bracket will come out. (yeah right). I stick a screwdriver under it and gently pry it up. After this is all clean - it's a moot point. It drops in easily and you just turn that set screw back in to tighten it. It's the dirt, grime, dust bunnies, etc that makes it seem difficult to get out.

|

| The position pin on the bottom of the part goes into a hole under the hook. The "Set Screw" under the bed is what holds it in place. |

With the OLDER model 66's, with a spoked hand wheel, there's no set screw under the hook area. It has a SOLID position finger that does NOT move and one screw that holds it down in there, instead of a riveted pin and set screw. Most manuals tell you to move over the position finger to get the bobbin case out. With this model - you can't. You have to remove the entire bracket to get the bobbin case out. I use a Chapman Bit #90 here.

4) Loosen the oscillating hook crank clamping screw (O, Fig 8)

5) Also loosen the presser bar bracket screw (M, Fig7) and raise the presser bar high enough to permit the sewing hook to be lifted from the machine.

This is another one of those steps that makes me chuckle. Such a simple sentence but SOOOO much work to make it happen after these old girls have been neglected for so long.....

So let me show you what screw they are talking about. The circled screw is the one that needs to be loosened. I use Chapman Bit #25.

Do yourself a favor and lubricate this area REALLY well before you go after the presser bar bracket screw (blue circle). I keep mentioning the Chapman Bits because they are, in my humble opinion, the most perfect fit on Singer Screws.

The bit fills the slot on the top of the screw so perfectly that unless you are being REALLY careless, you will avoid stripping the top of any screw. But I digress. The important thing to note here is that even if you get that set screw loose....that presser bar isn't going to move without some work. Lubricate with oil, PB Blaster if needed. The presser bar needs to be able to move up quite a bit to give the hook clearance to lift out. I also unscrew the Presser Bar Pressure screw (blue arrow) up at the top as far as it will go. If you take the Presser bar Pressure Screw OUT - watch you don't lose the washer that is right underneath it. Below is a picture to give you an idea of how much clearance you need to get the hook out.

So after ALL of that...let's talk about how to ACTUALLY get that hook out. Because you are probably looking at that picture and asking yourself.. "How in the hell did she do that?? That thing is NOT moving!"

Yeah - more lubrication, PB Blaster, etc. Take a look at the next photo if you can't get it out. The RED circle is the oil hole for the hook. Load that hole up good. The BLUE arrow is the screw that you loosened in Step 4. It's what clamps that piece onto the very bottom of the hook. If it's not loose enough - it's not going to go anywhere. The GREEN arrow is the end of a screwdriver pointing at the bottom of the hook piece. You can gently tap the handle end of a screwdriver to try to get it to move a little more.

Putting it all back:

So HOURS and HOURS later, after you have cleaned all the new areas you can get to and all the parts you removed, we want to put it back together. Well it's not just put everything back where you found it. We have a few things to tweak:

- We need to "time" the hook so that it will sew again!

- We need the feed dogs to be where we want them to be!

- We need that presser bar back in the right position and make sure our presser foot isn't crooked and applies pressure appropriately!

1) Put the hook back in the machine. Turn the balance wheel until the needle bar is in the lowest position. Put the hook in so that the hook tip is right around where the tip of the needle will be. (Don't worry - we will adjust this more precisely when we "time" the machine.)

2) Put the Bobbin Case Position Bracket back in the machine. Note: if you are working on the older model like i am - you will remove this again after the machine is in "time" and shimmy that bobbin case back in later.